NOW IN STOCK

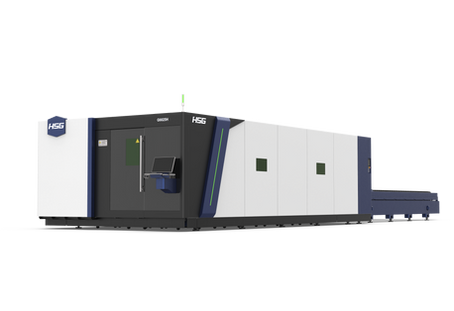

HSG GH Series

High Performance Fiber Laser Cutter

The HSG GH Series Laser Cutting Machines are capable of cutting through a variety of materials with high precision and power, including metals, plastics, and composites with exceptional accuracy and efficiency.

Equipped with a high-powered laser, these fiber laser cutting machines deliver fast and precise cutting with minimal heat-affected zones, ensuring clean and smooth edges on finished products. The user-friendly interface and advanced control system allow for easy operation and programming.

FEATURES AND BENEFITS

Upgraded Matrix Machine Bed with Level-up Rigidity

Brand-new matrix machine and welding design of the cross-section improve the rigidity of entire machine bed structure significantly and decrease the negative influence on machine bed.

High-precision Transmission System

Selected professional speed reducers, high-precision racks, guide rails and other accessories construct entire high-accuracy transmission system to ensure stable operations in long time.

Brand-new Aluminum Beam

The new fifth-generation 6-series aluminum beam has 20% less weight and 15% more torsional resistance than the previous generation. Lightweight design beams play a high dynamic performance of the equipment to improve processing efficiency.

Heat Protection Without Heat Damage Fear

Material waste device is made of high-density burn prohibition plates for further improving heat protection of the machine bed.

Bus-based Laser Cutting Heads

With power options ranging from 10kW to 40kW, ensuring stable cutting of thick sheets with precision. Incorporating optical filming technology to prevent lens pollution, preserving clarity and performance. Real-time monitoring of laser focus guarantees optimal cutting results. Plus, the bus-based height adjusting system enables seamless adjustment for enhanced accuracy and efficiency throughout the cutting process.

HSG Bus-based Control System

EtherCAT bus enables high-speed response with robust anti-interference capability and simplified electrical maintenance, while automated handling of machine maintenance includes real-time monitoring of key components, ensuring timely reminders for regular upkeep.